Since the establishment of the branch group within the engineering-design and all innovation – improvement activities, with the necessary infrastructure to provide the R & D center certificate in 2016 from the Ministry of Science, industry and technology responsible for design and R & D work in total 25 engineers involved in Ar started to work at the center

Clinker Cooler Unit Productivity Improvement Project:

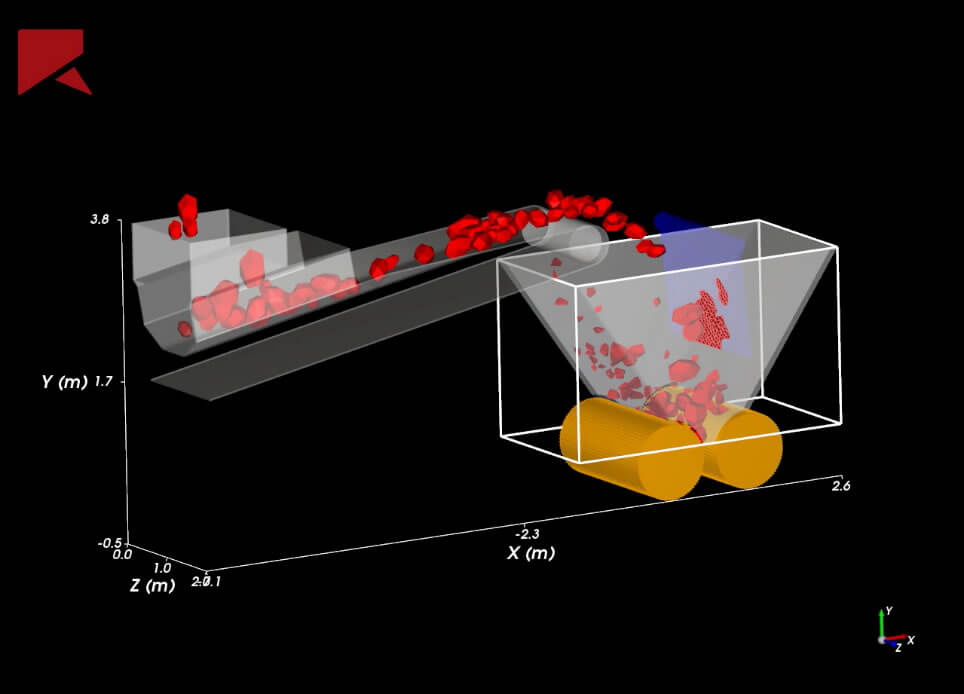

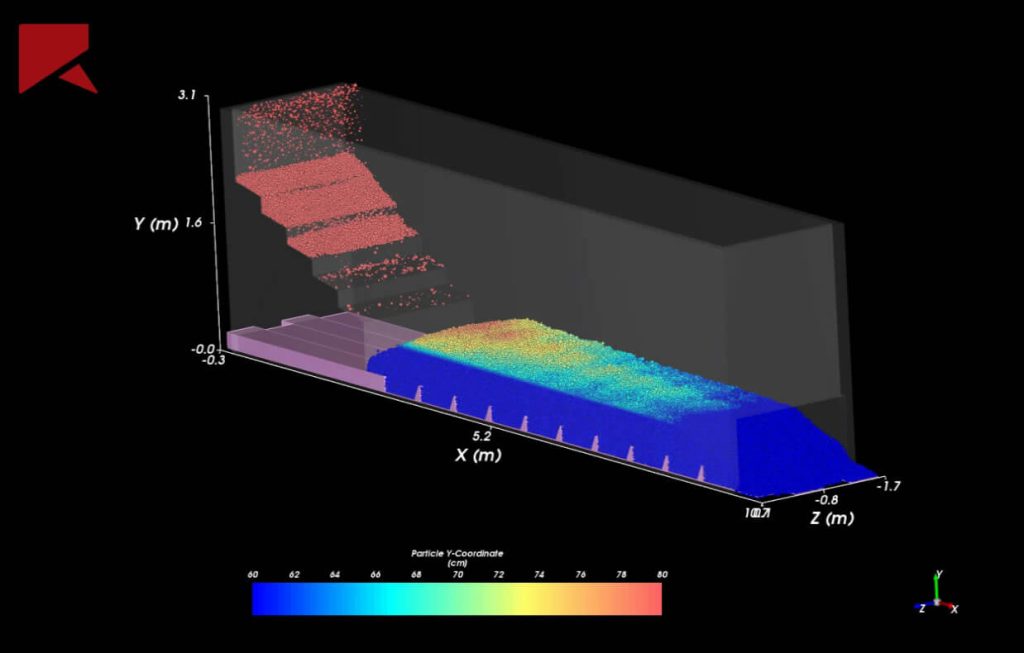

The purpose of the equipment is to increase the air temperature by passing the air taken from the atmosphere through the clinker coming from the rotary kiln and use it for combustion in the rotary kiln and calciner. The unit used for cooling determines the temperature increase in the air and the reduction in the amount of electricity consumed while feeding the air to the system. In order to increase the efficiency by changing the geometric and air flow parameters of the product with the R & D studies. Simulations of particle and fluid dynamics are utilized to see the effects of the changes. The process ends with the verification of the values found in the simulations with the test values.

Clinker Cooler Unit Productivity Improvement Project:

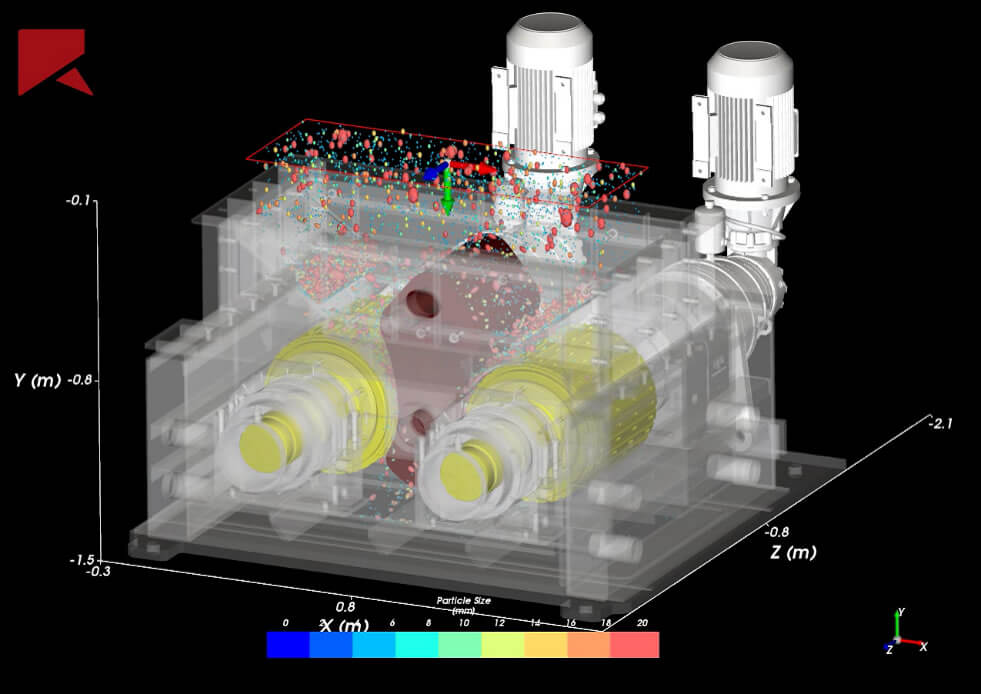

Clinker enters the clinker cooling unit in lava and tends to get together and cure due to the effect of cooling. In order to facilitate the transfer of the clinker between the different units and to reduce the mill capacity and mill power consumption, the hardened clinker must be broken and turned into small pieces. In this process, clinker breaker is needed. The performance of the clinker crusher is determined by the annual maintenance cost, the strength, the amount of crushing per unit power consumed and the particle size of the broken clinker. In the design and working principle of the clinker crusher, the final product is given by calculations and pre-prototype simulations.